|

|

|

ROSS INDUSTRIES was first to recognize the potential cost savings made possible

by applying impingement technology to product freezing.

|

˘Fast FreezeLow dehydrationHigh

product qualityŁ A thin boundary layer of air surrounds all objects and acts as insulation, reducing the rate of heat transfer. Ross BLC technology penetrates this insulating layer by directing high velocity, concentrated air streams at the surface of a food product from above and below. The Ross (B.L.C. = Boundary Layer Control) |

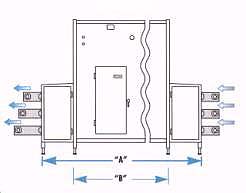

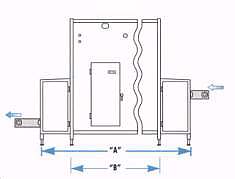

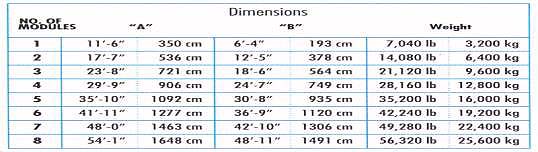

| Product Versatility The Ross BLC II is ideal for freezing flat products such as hamburger patties, chicken breasts or fish fillets. ItŐs also perfect for processing free flowing seafood, meat, fruit and vegetable IQF products. The modular construction of the BLC II ensures a minimal production area foot print while maximizing production throughput. And our unique On-Line Evaporator Defrost keeps you up and running with more efficiency than any other freezer on the market. Its three-level conveyor system allows optimum production flexibility. The BLC II can be configured to freeze different products independently in a straight line layout or IQF products ŇcascadedÓ as shown below. It also features top and bottom impingement on all levels to ensure uniform final product temperature. |

|

|

|

|

|

|

| @ |

|